Corrosion Analysis & Prevention

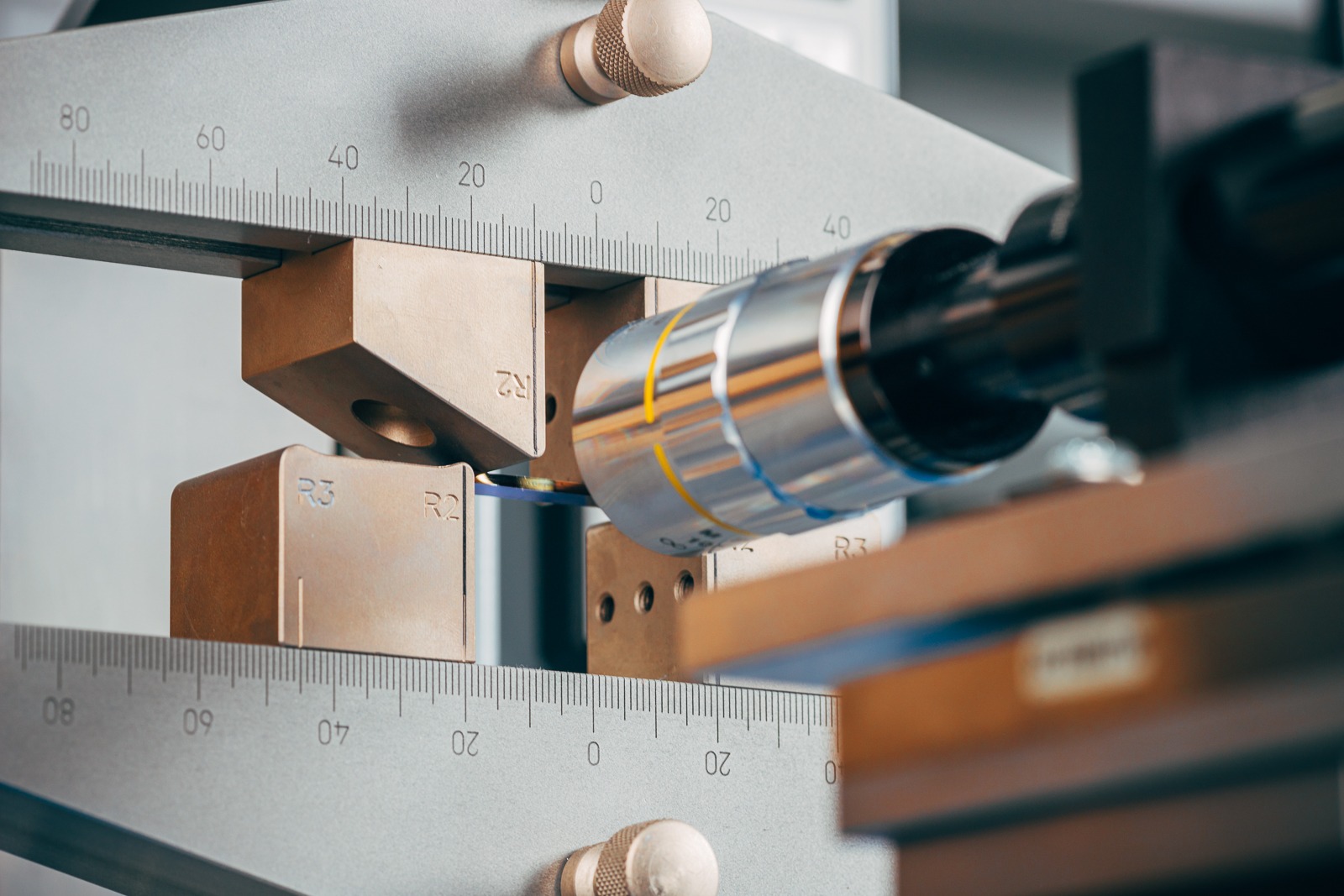

Analysis and understanding of device degradation enables us to continuously improve the robustness of semiconductor power devices.

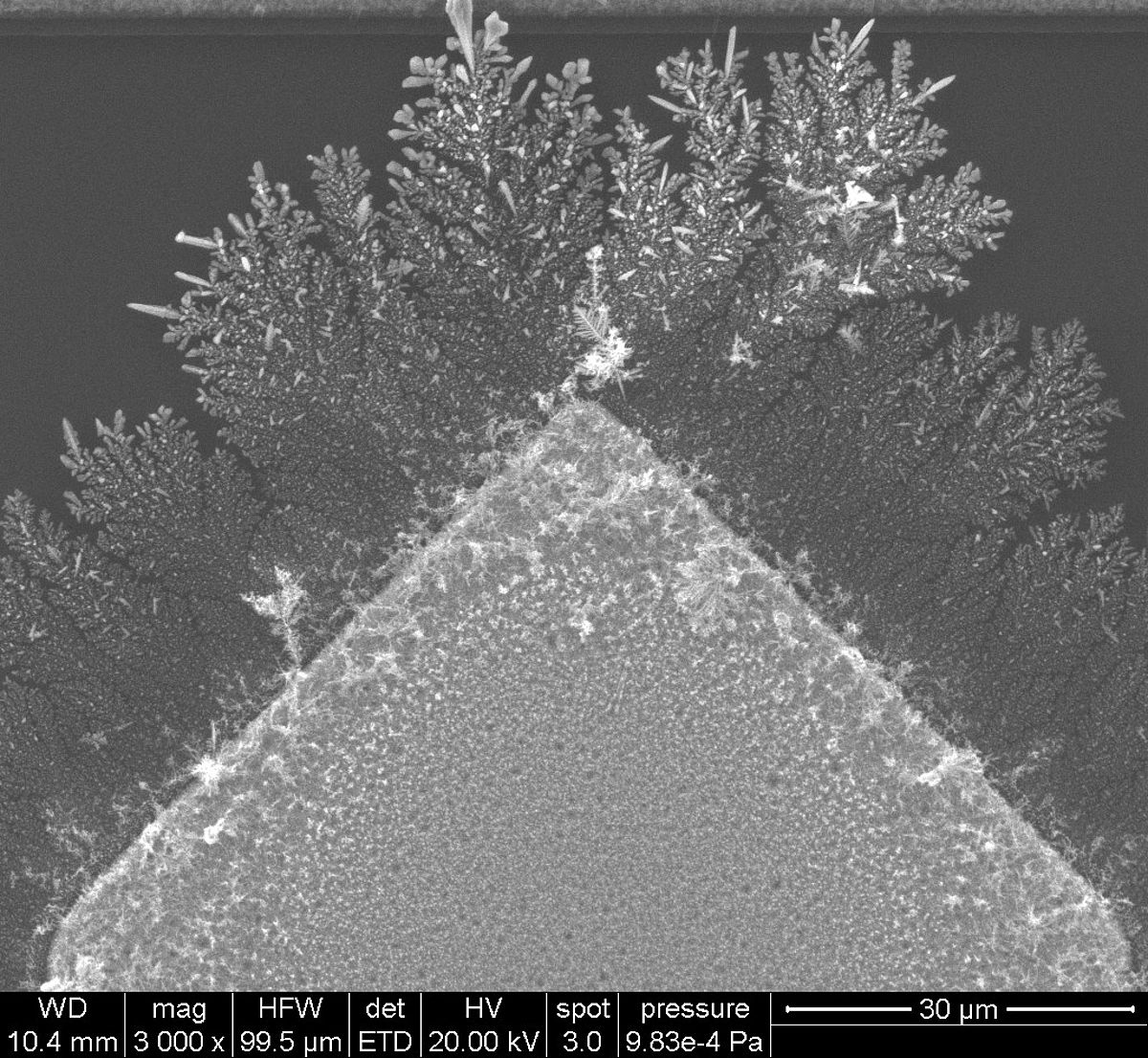

Diverse material combinations of miniaturized electronic components are a continuing challenge to ensure high level of reliability. Manufacturing processes and the operation of semiconductors under harsh environmaental conditions may cause an alteration of the material due to corrosion phenomena. In the worst case a complete failure of the device is unavoidable.

KAI Competences

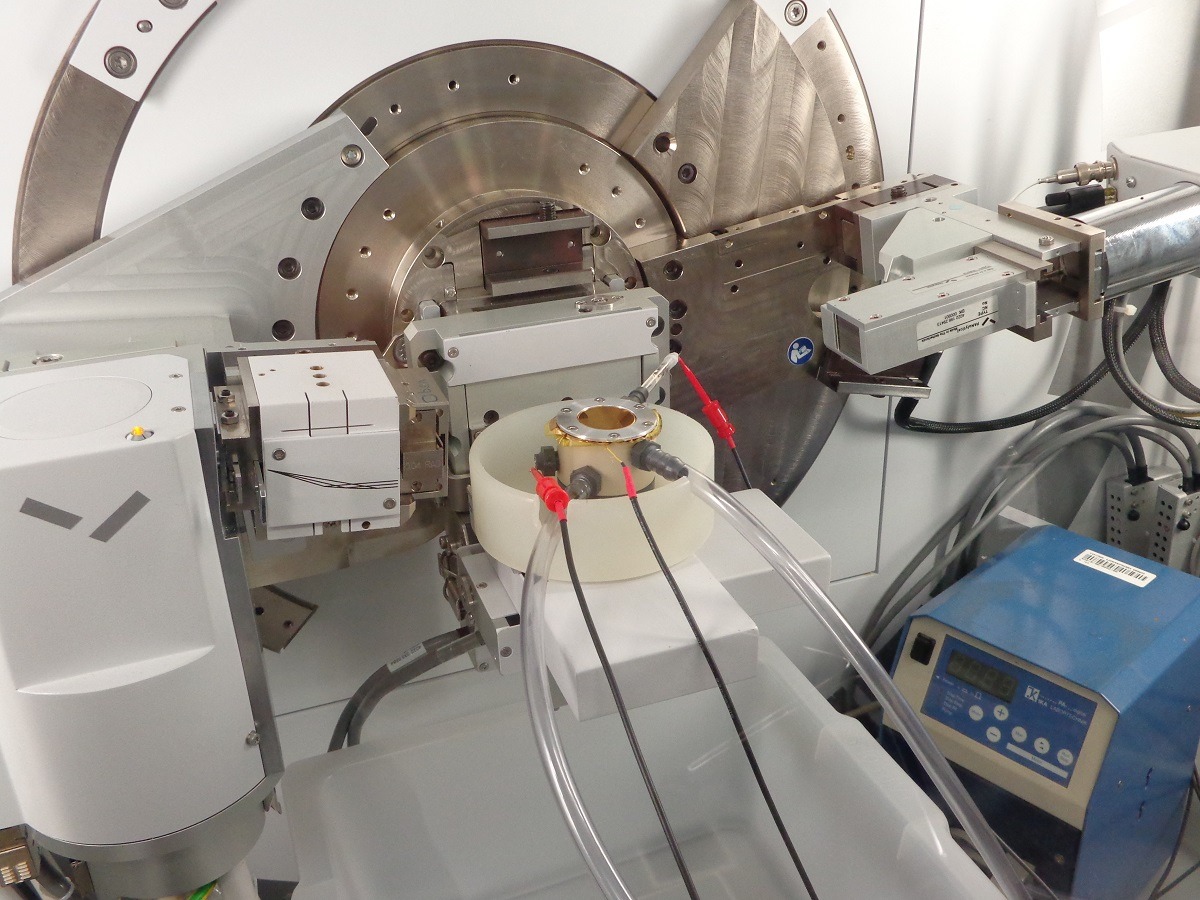

Together with the Institute of Chemical Technology and Analytics (CTA) and the Institute of Applied Synthetic Chemistry (IAS) at TU Wien, we are investigating the material behavior under simulated stress conditions for years to enhance their performance concerning corrosion resistance. Our expertise in combination with the knowledge of our academic partner and the quick access to electrochemical measurement methods (impedance spectroscopy, cyclic voltammetry, cycle stress test) and analytical tools provide the best conditions for studying corrosion of semiconductor devices.

Research Goals

A profound understanding of corrosion mechanisms of semiconductors stressed under varying parameters (i.e. voltage, temperature, humidity, contamination) is the key factor for process control, design of the semiconductor, material selection, invention of new materials and strategies to prevent corrosion.